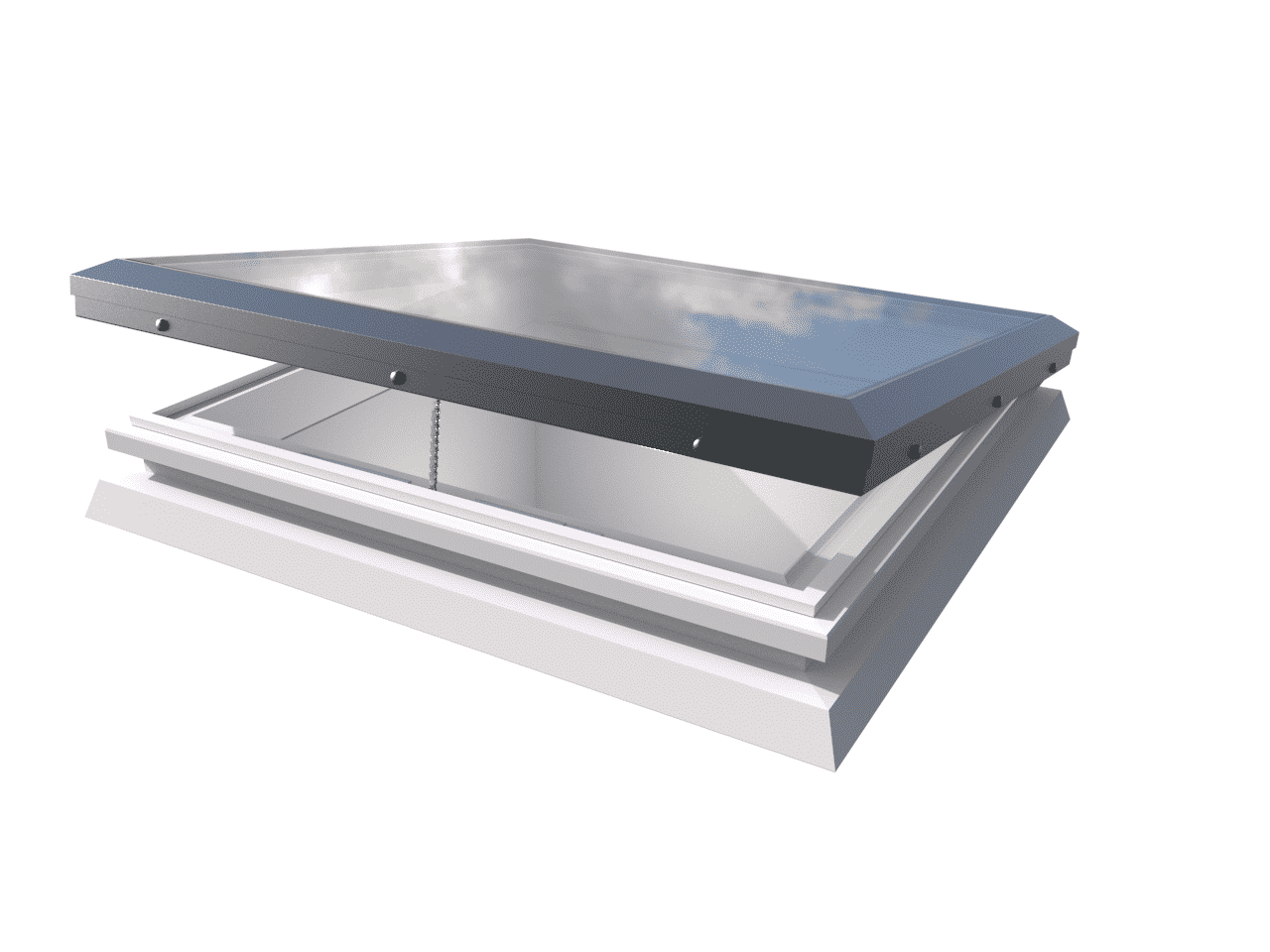

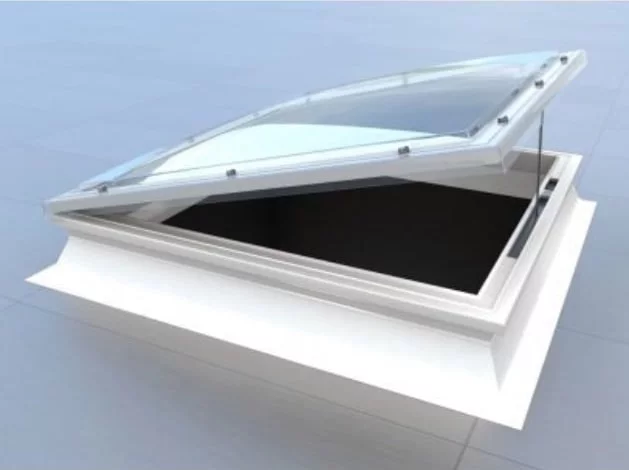

Our bespoke flat rooflights are perfect for visually expanding areas and other closed-in dark spaces, transforming them with daylight and stunning sky views. The seamless design with no joints ensures protection from water accumulation and mould build up. Choose a triple glazed rooflight for even more thermally efficiency.

We can also supply walk on glass rooflights. This product can be found by clicking the link below. For wall abutted rooflights or wall abutment rooflights please contact us for a custom quote.

Click here for walk on glass rooflights

What are the benefits of flat skylights?

Our flat roof skylights let in twice as much light as vertical windows and will make a great impact on your living environment. All our rooflights are made with high quality materials, making them reliable, long-lasting, attractive, and energy efficient. Our rooflights are custom-made to customer specifications to meet the desired u value required to comply with building regulations.

We also stock fixed rooflights, roof lanterns, opening rooflights, and more. For more CUSTOM fixed, electric or manual opening rooflights and roof lanterns please view our full collection of rooflights and skylights, or contact us to find out more.

You can also learn more about the differences between flat rooflights and roof lanterns in our expert blog.

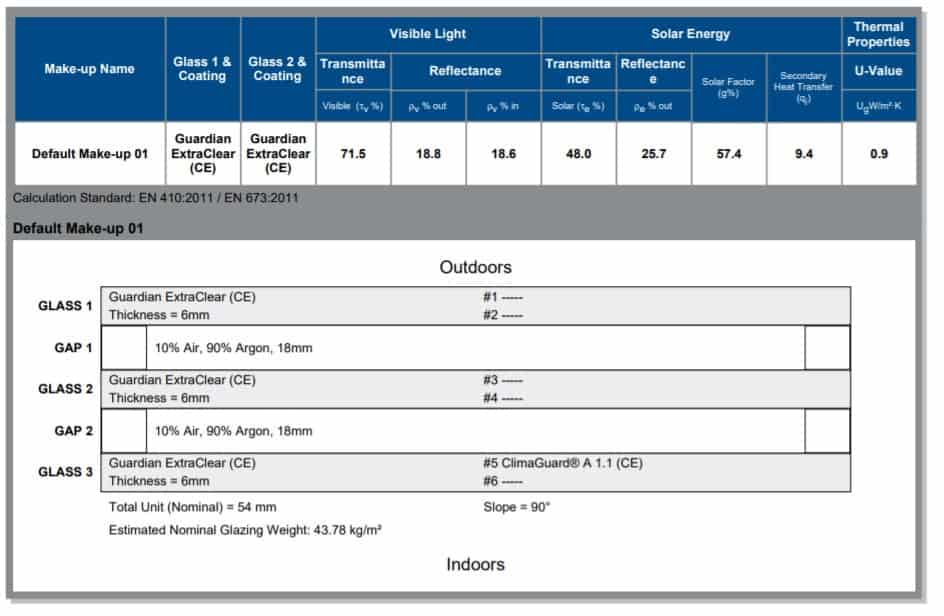

What are triple glazed rooflights?

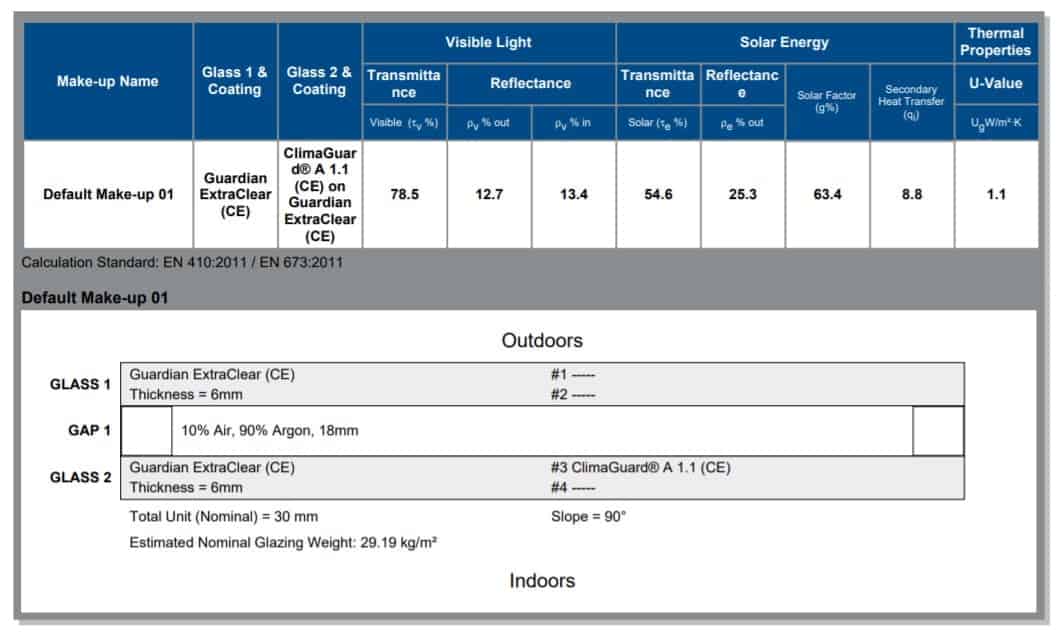

A rooflight is simply a window that is built into the roof. It could be a small, single pane of glass, or it could be a large and expansive rooflight that accounts for most of the roof. Triple glazing is effectively three panes of glass that are separated by argon gas. This latest innovation in window insulation is a step ahead of double-glazing.

So, with that in mind, read on to discover more about installing a triple glazed flat roof skylight.

What are the benefits of triple glazing for your flat roof skylight?

There are many benefits to gain by opting for a triple glazed rooflight over other options that are available. The main reason why people opt for triple glazing is because it is a better insulator. This means that less heat is going to escape your home through your newly installed roof light. While double-glazed flat roof lights also act as an effective barrier, triple glazing effectively adds another layer, further boosting the insulating qualities of the window. Not only does this mean a warmer home during the winter months, but it means lower energy bills too. After all, your home will stay warmer for longer, meaning you won’t need to have your central heating turned on as much. You can expect a much more peaceful home too. This is because the extra insulation also acts as a sound barrier. If that was not enough, triple glazing is also much more secure.

Now that you are aware of the best type of glazing for your roof lights, it is important to take a look at the other design elements that need to be considered when selecting flat glazed roof lights. Size is one of the major concerns here. Many customers miss out on the full range of benefits by choosing roof windows that are too small for the area of the room. Shape is also an important consideration, particularly in relation to size.

There is a common misconception that pyramid-style roof lights mean you can get more natural sunlight at a smaller size. You also need to consider what rooflight upstands you are going to choose. Upstands refer to the frames that the roof light sits in. You also need to think about roof access. If you have a roof garden, you need to insure the rooflight is just as beautiful from the exterior as it is from the interior.

Learn more about double glazing vs triple glazing in our helpful article.

Why choose Toughened Glass Systems for your triple glazed flat roof skylight?

We are flat roof window experts with years of experience in the industry. View our testimonials to see what our customers had to say about us, or read below for some key reasons to buy your flat rooflight from us.

Our flat roof window has passed strict independent testing

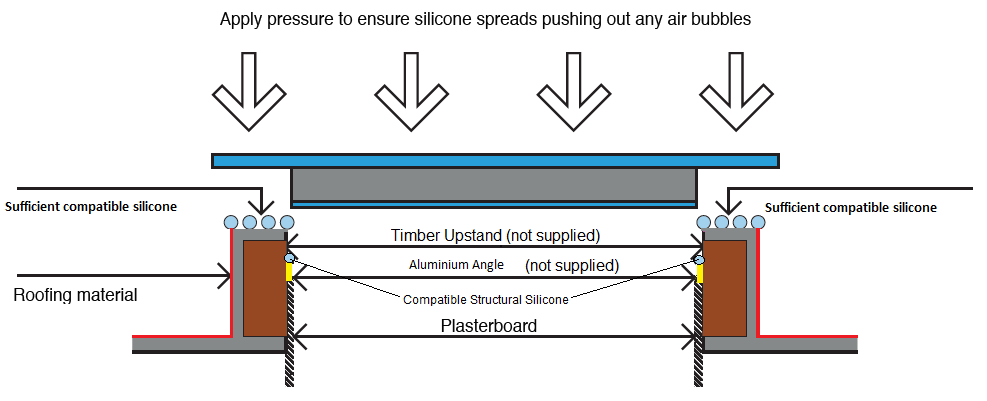

Unlike some of our competitors, this stepped rooflight system, once installed as per our fitting guide, has been through independent RVA accredited testing and met the requirements for Air Permeability (EN12207) and Water Tightness (EN12208).

Our flat roof windows let in more light

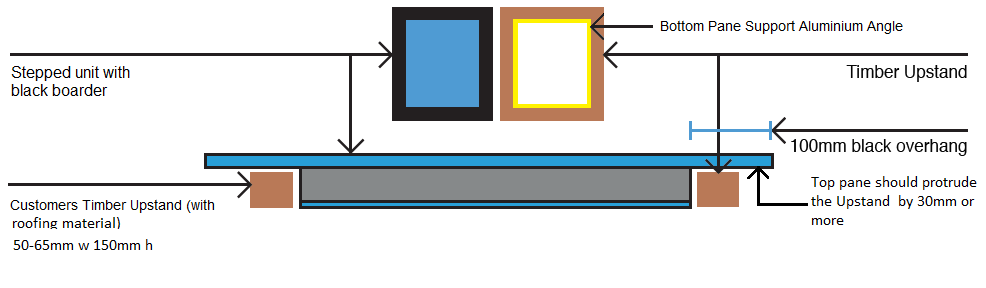

Please note, the size advertised on our drop-down menu is the visible bottom pane glass size – the top pane of glass is 100mm bigger all around. Most competitors will supply a rooflight with visible glass 200mm smaller than what they advertise. When comparing prices please consider this rooflight we supply lets in more light as the visible glass is larger.

Price match guarantee

We want you to get the best price for your purchase. This is why we promise to match the prices of other UK retailers.

High quality materials

We use high quality materials from reputable suppliers such as Pilkington in manufacturing our flat roof rooflights. This ensures the product is attractive and economical, with excellent thermal performance. Learn more about how rooflights can make your home more energy efficient in our helpful article.

More rooflights

As well as this rooflight for flat roofs, we also sell:

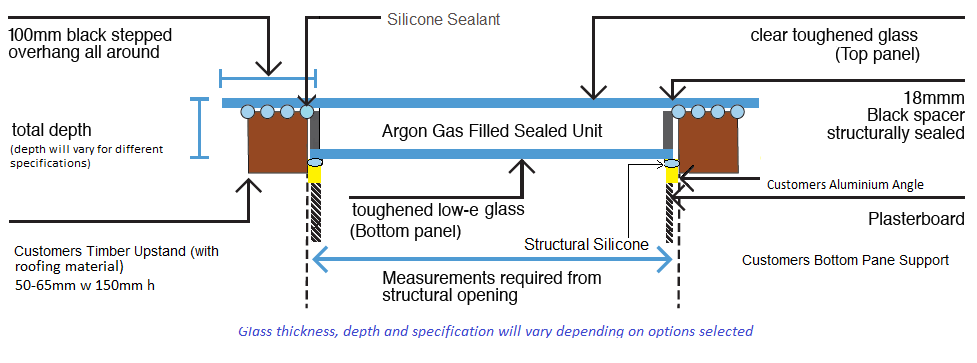

The first step in purchasing your rooflight would be to measure the structural opening where the rooflight will be installed. You should allow for 5mm tolerances all around to allow the bottom pane of the rooflight to fit smoothly into the opening. As an example, if your tight opening measurements are 1010mm by 1010mm we would recommend you purchase a rooflight with a bottom pane of 1000mm by 1000mm so it slots in smoothly.

The first step in purchasing your rooflight would be to measure the structural opening where the rooflight will be installed. You should allow for 5mm tolerances all around to allow the bottom pane of the rooflight to fit smoothly into the opening. As an example, if your tight opening measurements are 1010mm by 1010mm we would recommend you purchase a rooflight with a bottom pane of 1000mm by 1000mm so it slots in smoothly.